Are you planning a corrugated metal roof installation and wondering about the right slope? You’re asking the right question.

Roof slope, also known as pitch, refers to the angle at which your roof rises over a horizontal distance. This measurement directly affects how well water drains off your roof.

For corrugated metal roofing, slope isn’t just about aesthetics. It determines drainage efficiency, overall performance, and whether your installation meets local building codes.

Get it wrong, and you could face water pooling, leaks, or costly repairs down the road.

In this guide, you’ll learn the minimum slope requirements, factors that influence your decision, and practical tips for achieving optimal performance from your corrugated metal roof system.

Why Roof Slope Matters for Corrugated Metal Roofing

Roof slope directly determines how effectively water flows off your corrugated metal roof. When water moves quickly down the surface, it has less time to find weak points like seams or fastener holes, preventing pooling that leads to leaks and structural damage.

Weather resistance improves with proper slope because wind-driven rain has difficulty penetrating upward against gravity.

Steep surfaces shed snow and ice naturally, preventing dangerous accumulation that could overload your roof structure.

Overall performance depends on slope because corrugated panels rely on gravity to move water toward gutters.

Too little slope allows debris to collect in panel valleys, creating dams that force water backward under the roofing material.

Adequate slope ensures your metal roofing delivers long-term protection and extends material lifespan during severe weather conditions.

Understanding Roof Pitch Basics

Roof pitch expresses the steepness of your roof using a ratio of rise over run. For example, a 3:12 pitch meanse the roof rises 3 inches vertically for every 12 inches of horizontal distance.

Roofs fall into three main categories: low-slope (1:12 to 4:12), moderate pitch (4:12 to 9:12), and steep roofs (over 9:12). Each category requires specific materials and installation methods.

Proper slope ensures efficient water runoff that prevents pooling and potential leaks. Water moves quickly down steeper surfaces, reducing moisture contact time with roofing materials.

Snow and ice also shed more effectively on properly sloped roofs, preventing dangerous buildup and ice dam formation.

Adequate slope directly impacts your roof’s lifespan by minimizing moisture exposure and structural stress, making correct pitch selection a wise long-term investment for protecting both metal panels and the underlying roof structure.

Minimum Slope Requirements for Corrugated Metal Roofs

2:12 to 3:12 Minimum Slope

Most corrugated metal roofing systems require this range, depending on installation method and local conditions. This provides adequate drainage while accommodating various architectural styles and structural limitations.

Manufacturer Specifications Vary

Some premium corrugated panels may perform well at 1:12 slopes with proper underlayment and installation techniques. Always check your specific product’s installation manual before finalizing the roof pitch.

Building Code Requirements

Local weather patterns, snowfall amounts, and wind exposure can affect slope standards in your area. Building codes may establish minimum requirements that exceed manufacturer recommendations.

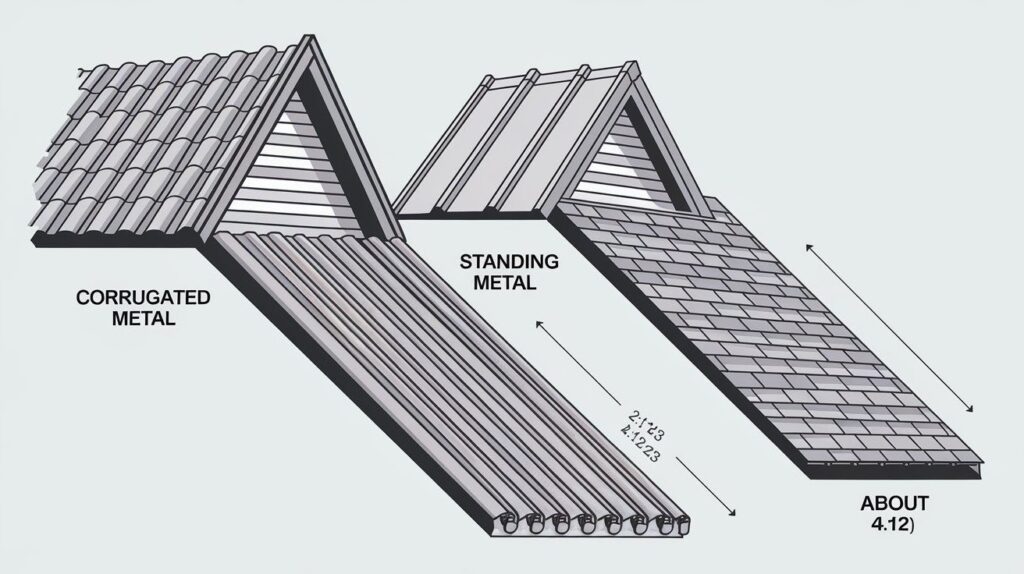

Comparison with Standing Seam: 1:12 Minimum

Standing seam panels can perform at lower slopes because their mechanically seamed joints provide superior weather protection. Corrugated panels need steeper slopes due to exposed fastener designs.

Comparison with Asphalt Shingles: 4:12 Minimum

Traditional shingles require steeper slopes than corrugated metal, making metal panels more versatile for low-slope applications where shingles would not be appropriate.

Factors That Affect the Minimum Slope

Local Climate Conditions

Heavy rainfall, snow loads, and wind exposure require steeper slopes for proper drainage and weather protection. Regional building codes establish minimum standards based on local weather patterns and decades of performance data.

Roof Design and Architecture

Simple roof shapes drain more efficiently than complex designs with valleys, dormers, and penetrations. Complex roofs often need steeper slopes to compensate for water concentration points and drainage challenges.

Panel Type and Installation Method

Exposed fastener panels require steeper slopes due to potential water entry through fastener holes. Hidden fastener systems perform better at lower slopes, while quality underlayments provide backup protection in all applications.

Pros and Cons of Low-Slope Corrugated Metal Roofs

Advantages

Low-slope corrugated metal roofs offer a sleek, modern aesthetic that complements contemporary architectural styles.

Cost-effectiveness makes these roofs attractive as metal panels typically cost less than premium materials while providing superior longevity.

Durability surpasses traditional asphalt shingles by decades, resisting weather damage, fire, and pest problems.

Disadvantages

Increased leak risk presents the primary concern as water moves more slowly off shallow pitches, creating opportunities for infiltration through seams or fastener holes.

Limited style options work best with simple roof shapes, restricting design flexibility compared to steeper installations.

Higher installation complexity requires experienced contractors and specialized materials, increasing both costs and labor requirements.

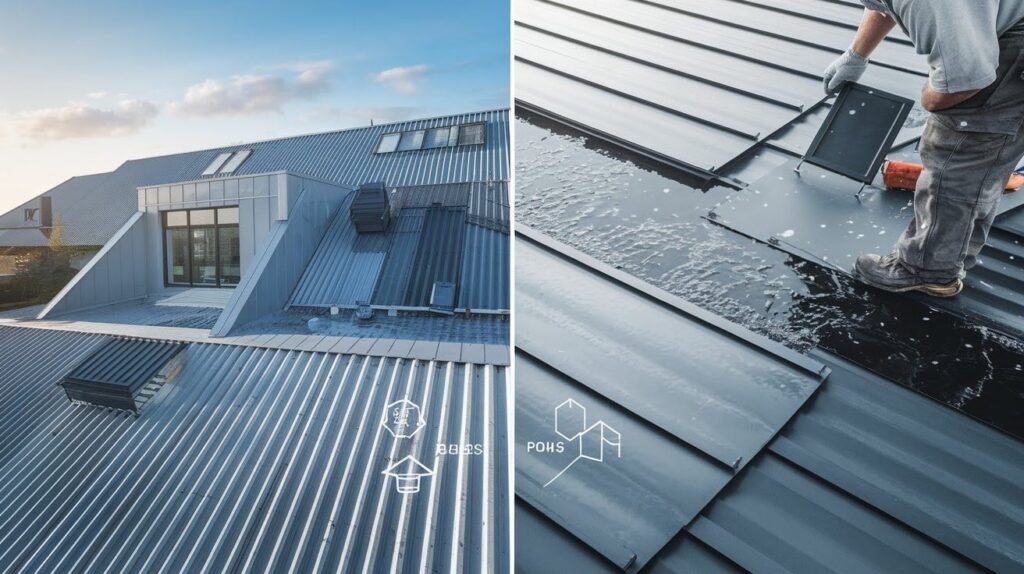

Tips for Installing Corrugated Metal on Low-Slope Roofs

- Use Approved Underlayments and Sealants: Self-adhering membranes and seam tape provide superior water protection. Proper flashing details around penetrations prevent infiltration at vulnerable points.

- Choose the Right Panel Length and Fastening System: Longer panels reduce horizontal seams and potential leak points. Hidden fastener systems eliminate exposed penetrations that can compromise roof integrity.

- Work With Experienced Contractors: Hire roofers who specialize in low-slope metal installations. Experienced installers ensure code compliance and protect your warranty coverage.

When to Consider a Steeper Pitch or Alternative Roofing

Increasing your roof slope beyond minimum requirements provides improved drainage that reduces leak risks and extends roof lifespan.

Steeper pitches offer more design flexibility for complex roof shapes and architectural features, while easier maintenance allows debris, snow, and ice to shed naturally without manual removal.

For very low slopes below corrugated metal minimums, consider mechanically seamed standing seam panels that perform well at 1:12 pitches using concealed fasteners and mechanical seams.

Alternatively, flat roofing systems like EPDM, TPO, or modified bitumen offer proven performance for slopes under 1:12, though they require different installation methods and maintenance approaches.

Conclusion

Getting your corrugated metal roof slope right from the start saves you headaches and money down the road.

Remember that most installations require a minimum 2:12 to 3:12 slope, though your specific product and local conditions may require adjustments to these guidelines.

Proper slope isn’t just a building code requirement. It’s your first line of defense against water damage, structural problems, and premature roof failure.

The extra effort you put into planning the correct pitch pays dividends in performance and longevity.

Don’t guess on something this important. Consult your manufacturer’s installation guidelines and work with experienced roofing professionals who understand low-slope metal applications.

Contact a trusted roofer today to evaluate your roof’s slope requirements and choose the right corrugated metal panels for your project.

Frequently Asked Questions

Can I skim coat over any type of wallpaper?

No, not all wallpapers are suitable for skim coating. Vinyl and heavily textured wallpapers can cause adhesion problems and bubbling issues that will show through your finished surface.

How do I test if my wallpaper is ready for skim coating?

Press firmly on different sections to check for loose areas, and try peeling a small corner. If the wallpaper lifts easily or feels spongy, removal is necessary before applying skim coat.

What happens if I skim coat over loose wallpaper?

The skim coat will follow the contours of any loose sections, creating bumps and uneven areas. These imperfections will become more visible once painted, requiring costly repairs.

Should I prime the wallpaper before skim coating?

Yes, always apply a high-quality primer designed for wallpaper surfaces. This prevents the wallpaper adhesive from reactivating and causing the skim coat to bubble or fail.

How thick should I apply the skim coat over wallpaper?

Apply thin, even coats of 1/8 inch or less. Multiple thin applications work better than one thick coat and reduce the risk of cracking or poor adhesion.