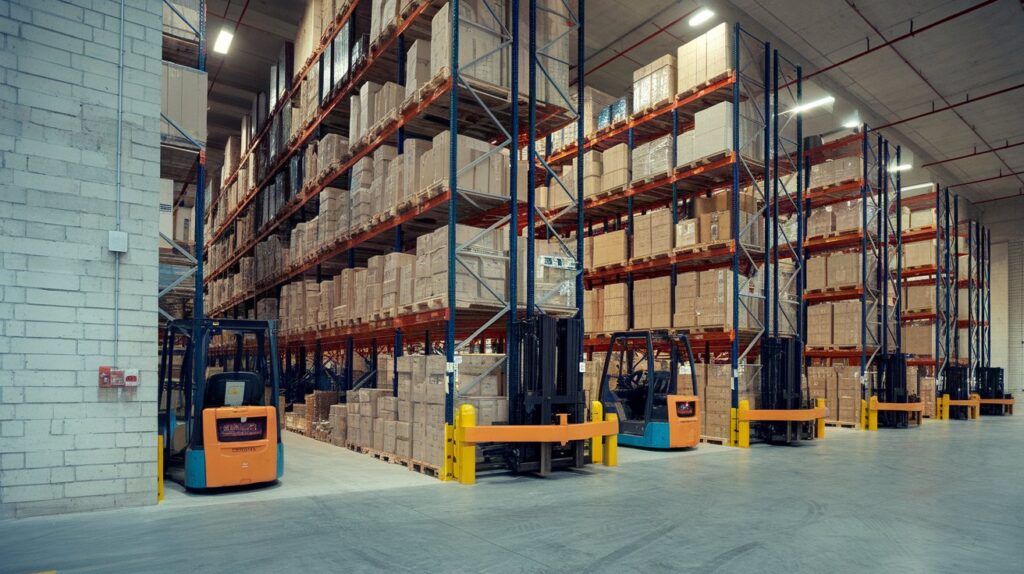

Setting up a new warehouse feels a bit like furnishing your first apartment. Except instead of debating whether you really need that expensive couch, you’re staring at massive steel structures wondering how much it’ll cost to store thousands of pallets properly.

The truth is, warehouse racking costs can swing wildly depending on what you’re after. Let’s break down what you’re actually looking at price-wise.

Basic Pallet Racking Won’t Break the Bank

Your standard selective pallet racking is pretty much the Honda Civic of warehouse storage. It gets the job done without any fancy bells and whistles. You’re looking at roughly $80 to $150 per pallet position for basic setups.

Actually, that range covers a lot of variables. Height matters more than you’d think. A three-level system costs significantly less than something reaching up to the ceiling. The thing is, most warehouse managers get sticker shock at first, then realize they’re comparing apples to oranges when they see quotes.

Drive-In Systems: More Storage, More Money

Here’s where things get interesting. Drive-in racking lets you pack way more pallets into the same footprint, but you’ll pay for that efficiency. Expect costs to jump to around $120 to $200 per pallet position.

The upside? You can fit roughly twice as much stock in the same floor area. The downside? Your forklift drivers need to be pretty skilled, and you’re committed to a last-in, first-out system. Works great for bulk storage of the same product, not so much if you need quick access to everything.

When You Need to Go Up: Mezzanine Solutions

Sometimes the answer isn’t just more racking. Sometimes you need more floor entirely. Companies like Storeplan specialize in mezzanine solutions that essentially double your usable warehouse space by adding another level.

Mezzanine costs vary wildly based on load requirements and complexity, but you’re typically looking at $150 to $300 per square meter. Sounds expensive until you realize you’re getting double the space without moving to a bigger building.

The Hidden Costs Nobody Mentions

Here’s what catches people off guard. The racking itself is just part of the equation. Installation can add another 15% to 25% to your total cost. Then there’s engineering approval, which is mandatory but often forgotten in initial quotes.

Safety equipment adds up too. Rack protection guards, safety netting, and proper signage aren’t optional extras. They’re essential, and they’ll tack on a few thousand more to your bill.

High-Density Options for Maximum Efficiency

Mobile racking systems represent the premium end of warehouse storage. These setups can double or even triple your storage density, but they come with premium pricing. You’re looking at $400 to $800 per pallet position.

The numbers sound scary, but the math often works out. If you can avoid moving to a larger facility by maximizing your current space, the investment pays for itself pretty quickly through saved rent and operational costs.

Getting Your Numbers Right

Most warehouse managers underestimate their actual needs by about 20%. It’s better to plan for growth from the start than to retrofit later. Adding to existing racking systems always costs more per unit than installing everything at once.

The other thing worth considering is lead times. Custom racking solutions can take 8 to 12 weeks from order to installation. Standard configurations move faster, but even basic setups require a few weeks.

To be honest, the best approach is getting detailed quotes from multiple suppliers. Every warehouse is different, and what works perfectly for one operation might be completely wrong for another. The key is finding the right balance between capacity, accessibility, and budget constraints.

Your specific costs will depend on your unique requirements, but at least now you know what ballpark you’re playing in.