Choosing the wrong corrugated metal roof type can cost you thousands in repairs and replacements.

I’ve installed over 200 metal roofs in my years as a contractor. Seven main types of corrugated metal roofing exist, each with different benefits and drawbacks.

This guide covers all corrugated metal roof types, from budget-friendly galvanized steel to premium copper options. You’ll learn which type fits your climate, budget, and building needs.

I’ll share real costs, maintenance requirements, and installation tips. Plus, you’ll get my proven decision framework for picking the perfect metal roof.

No sales pitches. Just honest advice from someone who’s seen every roofing mistake possible.

Here’s what you’ll learn: material comparisons, cost breakdowns, maintenance schedules, climate considerations, and my top recommendations for different situations.

Let’s find your ideal corrugated metal roof type.

What is Corrugated Metal Roofing?

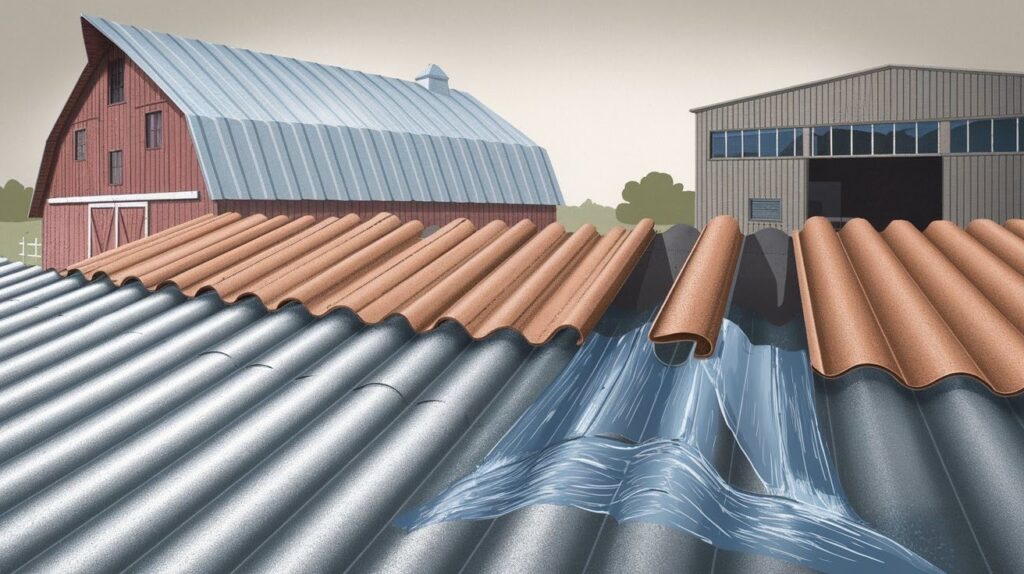

Think of those wavy metal sheets you see on barns and industrial buildings. That’s corrugated metal roofing.

The word “corrugated” means shaped into ridges and grooves. These waves aren’t just for looks. They make the metal incredibly strong while keeping it lightweight.

The ridges channel water away quickly. The pattern adds structural strength. It’s much lighter than traditional shingles. Installation is faster than most roofing materials.

7/8 Inch vs 1/2 Inch Corrugated Profile Comparison

Before diving into material types, you need to understand the two main corrugated profiles available.

The measurement refers to the depth of the corrugation from peak to valley.

| Feature | 7/8 Inch Profile | 1/2 Inch Profile |

| Structural Strength | Superior – spans up to 5 feet between purlins | Good – requires closer purlin spacing (3-4 feet) |

| Water Shedding | Excellent – deeper channels handle heavy rainfall | Good – adequate for most climates |

| Wind Resistance | Better rigidity against uplift forces | Adequate with proper fastening |

| Cost | 10-15% higher material cost | Lower initial investment |

| Appearance | Bold, pronounced shadow lines | Subtle, traditional corrugated look |

| Installation | Fewer purlins needed due to longer spans | More purlins required for proper support |

| Maintenance | Self-cleaning profile sheds debris better | May require more frequent cleaning |

My Professional Recommendation

I recommend 7/8 inch corrugated for most residential and commercial applications. The additional structural strength and superior water management justify the modest cost increase.

Choose 1/2 inch corrugated when budget is the primary concern, for temporary structures, or when matching existing 1/2 inch profiles on adjacent buildings.

For coastal areas, high-snow regions, or spans over 4 feet, always go with 7/8 inch profiles. The performance difference becomes critical in challenging conditions.

Main Corrugated Metal Roof Types

1. Galvanized Corrugated Metal Roof

This is the classic choice. Steel coated with zinc for protection.

What you get: rust resistance that lasts 20-30 years, budget-friendly pricing, easy repairs when needed, and wide availability at most suppliers.

Galvanized roofing works great for most climates. The zinc coating protects the steel underneath from rust and corrosion.

I recommend this for first-time metal roof buyers and budget-conscious projects.

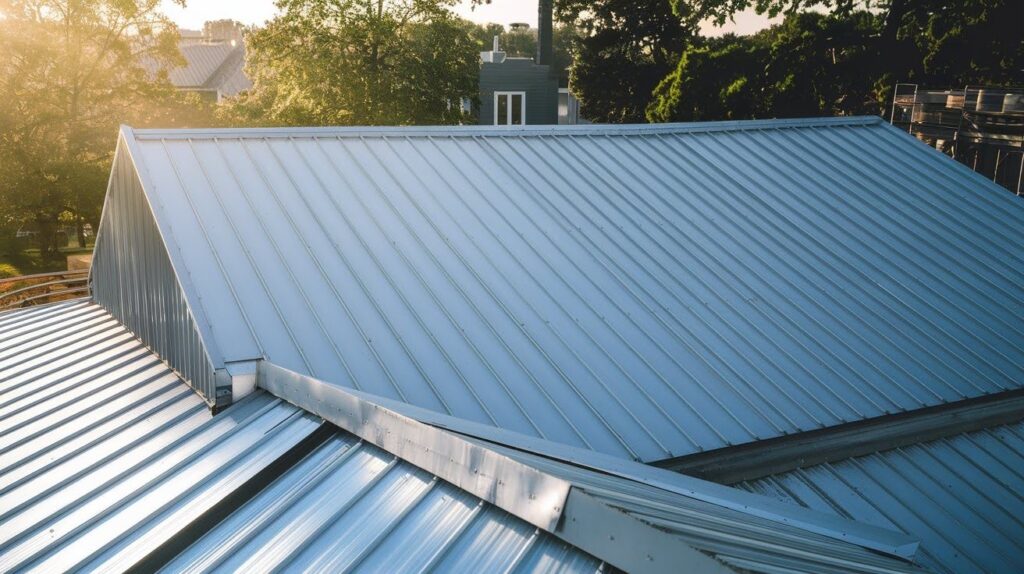

2. Galvalume Corrugated Metal Roof

Think of this as galvanized steel’s upgraded cousin. Instead of pure zinc coating, Galvalume uses a mix of zinc and aluminum.

This combo gives you better protection against the elements. You get a longer lifespan of 30-50 years, better heat reflection, superior corrosion resistance, and self-healing properties when scratched.

The aluminum in the coating reflects heat better than plain galvanized steel. Your energy bills will thank you.

I suggest this for coastal areas, hot climates, and long-term investment seekers.

3. Aluminum Corrugated Roof

This is the lightweight champion of the metal roofing world.

Aluminum naturally resists rust. No coating needed. It’s also incredibly light, which means less stress on your home’s structure.

Why choose aluminum: it never rusts naturally, it’s extremely lightweight, great for coastal areas, and has excellent heat reflection.

The downside? It dents easier than steel options.

I recommend this for older homes with weight concerns and coastal properties.

4. Stainless Steel Corrugated Roof

This is the premium choice for extreme conditions.

Stainless steel contains chromium, which creates an invisible protective layer. This makes it virtually indestructible.

What makes it special: exceptional durability of 50+ years, fire resistance, no maintenance required, and it handles extreme weather.

Yes, it costs more upfront. But you’ll likely never need to replace it.

I suggest this for commercial buildings and fire-prone areas.

5. Copper Corrugated Metal Roof

The showstopper that gets better with age.

Copper starts bright and shiny, then develops a green patina over time. This natural aging process actually protects the metal.

Copper advantages: impressive appearance, 100+ year lifespan, naturally antimicrobial, and develops protective patina.

It’s expensive, but copper roofing is often the last roof your building will ever need.

I recommend this for historic homes and luxury projects.

6. Painted Corrugated Metal Panels

Any of the above metals can come pre-painted.

Paint systems today resist fading, chalking, and peeling much better than older coatings. Popular paint options include PVDF coatings for maximum durability and polyester paints for good value.

Paint adds about 10-15 years to your roof’s appearance.

7. Zinc Corrugated Roof

The environmentally conscious choice that’s gaining popularity among builders.

Zinc is completely recyclable and develops its own protective coating over time. It requires minimal maintenance and offers a distinctive weathered look that many architects prefer.

Zinc benefits: 100% recyclable material, self-healing surface properties, low maintenance requirements, and develops an attractive weathered patina.

The material starts with a bright metallic finish, then gradually develops a matte gray patina that protects against corrosion.

I recommend this for green building projects and modern architectural designs.

Corrugated Metal Roof Cost Breakdown

Here’s what you can expect to pay per square foot installed:

| Metal Type | Cost Per Square Foot |

| Galvanized Steel | $3.50 – $5.50 |

| Galvalume | $4.00 – $6.50 |

| Aluminum | $4.50 – $7.00 |

| Stainless Steel | $8.00 – $12.00 |

| Copper | $12.00 – $18.00 |

| Zinc | $10.00 – $15.00 |

Additional costs to consider:

| Component | Cost Range |

| Underlayment | $0.50 – $1.00 per sq ft |

| Trim and Flashing | $2.00 – $4.00 per linear ft |

| Ridge Caps | $3.00 – $6.00 per linear ft |

| Labor | $2.00 – $5.00 per sq ft |

Money-saving tips from my experience: get quotes from multiple contractors, consider doing tear-offs yourself, buy during off-season for better prices, and choose standard colors over custom ones.

Pros and Cons of Corrugated Metal Roofing

Let me give you the honest truth about corrugated metal roofing.

| Pros | Cons |

| Durability lasts 40-70 years with minimal maintenance | Noise during rain can be louder than other materials |

| Excellent weather resistance against wind, hail, and snow | Denting potential with hail or falling branches |

| Fire safety – metal roofing is non-combustible | Thermal expansion occurs with temperature changes |

| Energy efficiency – reduces cooling costs by 10-25% | Higher initial cost than basic shingles |

| Fast installation compared to traditional shingles | Walking on roof can scratch painted surfaces |

| Low maintenance requirements | Professional installation recommended for warranties |

| Lightweight – less stress on home structure | Limited color choices compared to other materials |

| Recyclable at end of life | Can amplify sound from rain or hail |

Most cons can be minimized with proper installation and material selection.

Corrugated Metal Roof Maintenance Tips

I tell all my customers that good maintenance keeps your roof looking great and performing well.

- Check fasteners annually for looseness or rust, and inspect seams for potential problems

- Clean with mild soap and water only – avoid harsh chemicals or pressure washing that can damage coatings

- Remove debris regularly since leaves and branches trap moisture and can cause corrosion

- Apply touch-up paint to scratches immediately to prevent rust from spreading underneath

- Schedule professional inspections every 3-5 years for loose panels, leaks, or structural damage

I always recommend taking photos during installation. They help identify problems later.

Choosing the Right Corrugated Metal Roof Type for You

Here’s my decision framework for picking the perfect corrugated metal roof.

Budget Considerations:

- Tight budget: Galvanized steel gives you metal roofing benefits at the lowest cost

- Moderate budget: Galvalume offers the best performance and value combination

- Premium budget: Consider aluminum, copper, or stainless steel for maximum longevity

Climate Factors:

- Hot climates: Light colors and reflective coatings reduce cooling costs significantly

- Coastal areas: Aluminum or marine-grade coatings resist salt corrosion damage

- High wind zones: Use heavier gauge metals with proper attachment systems

Building Type: For residential projects, focus on appearance, energy efficiency, and longevity. For agricultural buildings, prioritize cost and weather protection.

My top recommendations: Galvalume with 30-year paint warranty for overall value, galvanized steel 26-gauge minimum for budget choice, and aluminum with PVDF coating for premium option.

Remember: quality installation matters more than material choice, and local building codes affect material requirements.

Conclusion

I’ve given you everything needed to make a smart decision. Seven metal types, real costs, and honest pros and cons.

My top recommendation remains Galvalume with a 30-year paint warranty. It offers the best balance of performance, cost, and durability for most homes.

Don’t rush this decision. Your roof will protect your family for decades. Take time to get three quotes from experienced metal roofing contractors in your area.

Compare their material recommendations, installation methods, and warranty terms. Ask tough questions about gauge thickness, fastening systems, and thermal expansion handling.

Start your research today. Contact local contractors, visit showrooms, and see installed examples in person.

Your perfect corrugated metal roof is waiting. Make it happen.

Frequently Asked Questions

How long do corrugated metal roofs actually last?

Most corrugated metal roofs last 40-70 years with proper installation and maintenance. Galvanized steel lasts 20-30 years, while premium options like copper can exceed 100 years.

Can I install corrugated metal roofing myself?

Yes, but only if you have roofing experience and proper safety equipment. Aluminum panels are lightest for DIY projects, though professional installation ensures warranty coverage and proper weatherproofing.

Do metal roofs make houses too hot in summer?

Actually, no. Reflective metal roofing can reduce cooling costs by 10-25% compared to dark shingles. Light-colored panels with reflective coatings work best in hot climates.

Will hail damage my corrugated metal roof?

Most corrugated metal roofs resist hail damage better than shingles. Heavier gauge metals like steel handle impacts better than aluminum, though large hailstones can dent any metal roofing.

What’s the difference between corrugated and standing seam metal roofing?

Corrugated has visible ridges and exposed fasteners, making it more affordable. Standing seam has hidden fasteners and flat panels with raised seams, offering better weather protection at higher cost.