You walk into your office building every morning. But have you ever looked up and wondered what protects you from rain, snow, and scorching heat?

Meet single-ply roofing.

It’s one continuous membrane that covers your entire roof. Think of it like a giant protective blanket stretched across the top of a building.

Here’s why building owners love it: Single-ply systems work incredibly well on flat and low-slope roofs. You know those big box stores and warehouses you see everywhere? Most of them use this roofing type.

The installation is faster than traditional methods. Repairs are simpler, too. Plus, these systems can last decades with proper care.

Commercial property managers choose single-layer roofing because it offers reliable protection without breaking the budget.

What Is Single-Ply Roofing?

Single-ply means one layer. One membrane. Traditional roofs stack multiple layers, like wearing three sweaters at once. Single-ply roofing is different.

One strong membrane does everything. No extra layers needed. Old asphalt roofs need felt paper, tar, gravel, and more tar. Layer after layer. Weeks of work.

Single-ply systems? Roll out the membrane. Secure it. Done. This one material handles water, UV rays, temperature swings, and wind.

Fewer layers mean fewer leak points. Smart building owners love this simplicity.

Benefits of Single-Ply Roofing Systems

- Durability and Weather Resistance: Single-ply membranes handle extreme weather like hailstorms, heavy snow, and blazing sun. Most come with 20-year warranties and last even longer with proper care.

- Energy Efficiency and Cool Roof Capabilities: White and light-colored membranes reflect heat, keeping buildings cooler naturally. This reduces air conditioning costs and can save building owners thousands annually.

- Lightweight and Easy Installation: These membranes weigh much less than traditional roofing, so no building reinforcement is needed. Installation crews can finish large roofs in days instead of weeks.

- Cost-Effectiveness for Large Projects: The bigger your roof, the more you save with single-ply systems. Material and labor costs stay predictable, and maintenance remains simple and affordable.

- Sustainability and Eco-Friendly Options: Many single-ply membranes are recyclable and contain recycled content. Cool roof properties help reduce urban heat while earning your building green credits.

Types of Single-Ply Roofing Membranes

Single-ply membranes come in thermoplastic and thermoset varieties, each offering unique benefits for different climates and applications.

Thermoplastic Membranes (Heat-Weldable)

1. TPO (Thermoplastic Polyolefin)

TPO offers excellent UV resistance and cooling benefits at an affordable price. These white membranes reflect heat effectively, reducing energy costs. Typical lifespan ranges from 15-20 years, making them popular for warehouses, retail stores, and office buildings.

2. PVC (Polyvinyl Chloride)

PVC membranes provide superior strength, fire resistance, and chemical resistance with excellent flexibility. They perform exceptionally well in restaurants, warm climates, and high-wind zones. The welded seams create watertight bonds that last for decades.

Thermoset Membranes (Adhesive-Based)

1. EPDM (Ethylene Propylene Diene Monomer)

This rubber-based membrane offers outstanding durability and elasticity, especially in cold climates. EPDM excels in hail-prone regions and areas with frequent freeze-thaw cycles. The black surface absorbs heat, which can benefit buildings in colder regions.

2. FPO (Flexible Polyolefin)

FPO provides a sustainable alternative with both mechanical and adhered installation options. This membrane combines the best features of TPO and EPDM while offering improved puncture resistance and flexibility in various weather conditions.

Single-Ply Roofing System Assemblies

Single-ply systems are installed using four main methods, each suited for different building requirements and environmental conditions.

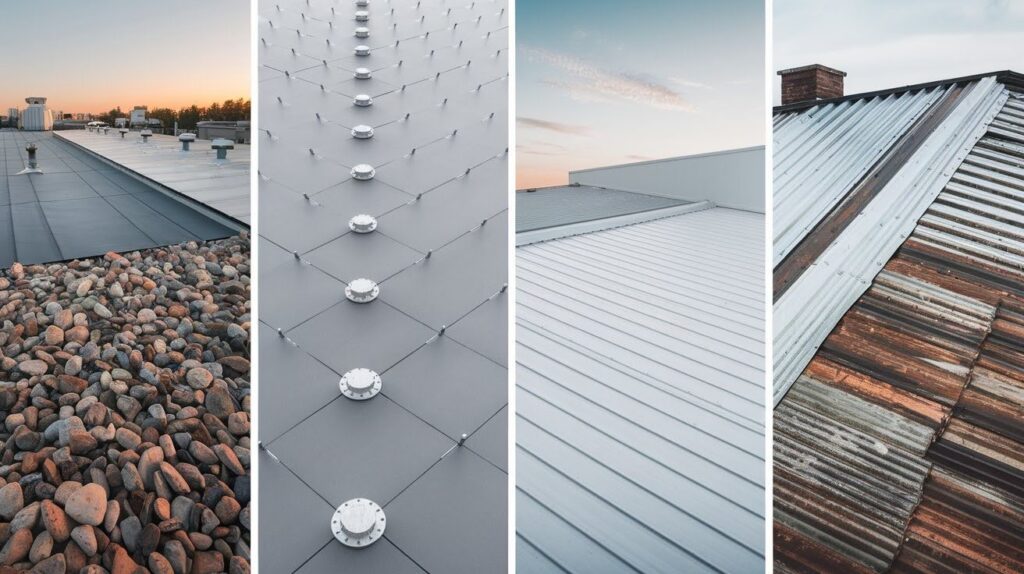

Ballasted Systems

Ballasted Systems use heavy stones or pavers to hold the membrane in place. No fasteners pierce the roof deck.

This method works best on large, flat rooftops with strong structural support. Installation is fast and economical.

Mechanically Attached Systems

Mechanically Attached Systems use fasteners and plates to secure the membrane. The lightweight design makes maintenance easy.

These systems resist strong winds effectively. They work well on roofs that can’t support heavy ballast.

Fully Adhered Systems

Fully Adhered Systems bond the entire membrane to the roof deck with adhesive. This creates maximum stability and uplift protection.

High-wind areas and high-elevation buildings benefit most from this method. The complete adhesion prevents membrane movement.

Metal Retrofit Systems

Metal Retrofit Systems are installed over existing metal roofs without removal. This saves tear-off costs and disposal fees.

The new membrane encapsulates the old roof completely. Installation time reduces significantly compared to full replacement.

Single-Ply Roofing Lifespan and Maintenance

- Most single-ply membranes last between 15 and 30 years with proper installation and care. TPO provides 15-20 years, PVC reaches 20-25 years, and EPDM can last 25-30 years.

- Installation quality makes the biggest difference in roof lifespan as poor workmanship leads to early failures. Climate factors like extreme temperatures, UV exposure, and severe weather also reduce membrane life significantly.

- Regular upkeep extends performance significantly and buildings with maintenance programs see roofs last much longer. Small repairs handled promptly prevent major problems from developing over time.

- Annual inspections catch problems before they become expensive disasters. Professional inspections cost hundreds while roof replacement costs thousands, making regular checkups a smart investment.

- Clogged drains cause ponding water that damages membranes over time if not addressed quickly. Small tears and loose seams are easy to fix when found early during routine maintenance.

- Smart building owners schedule regular checkups and handle minor repairs promptly. This proactive approach maximizes roof lifespan and minimizes unexpected replacement costs.

Conclusion

After years in the roofing industry, I’ve seen single-ply systems prove their worth time and again. They offer unmatched durability, energy savings, and cost-effectiveness that traditional roofs simply can’t match.

Commercial and industrial property owners choose single-ply because it works. Fast installation means less downtime for your business. Lower maintenance costs keep your budget intact. Energy savings add up year after year.

But here’s what I tell every client: your building is unique. Your climate is different. Your budget has specific requirements.

Don’t guess on something this important. Reach out to a qualified roofing professional who understands single-ply systems. They’ll assess your specific needs and recommend the right membrane and installation method.

Your roof protects everything underneath it. Make sure you get it right.

Frequently Asked Questions

How long does single-ply roofing last?

Single-ply membranes typically last 15-30 years, depending on the material and installation quality. TPO lasts 15-20 years, while EPDM can reach 25-30 years with proper maintenance.

Is single-ply roofing better than traditional roofing?

Single-ply systems offer faster installation, lower weight, and fewer leak points compared to multi-layer roofs. They’re also more energy-efficient and cost-effective for large commercial buildings.

What’s the difference between TPO and EPDM membranes?

TPO is a white thermoplastic membrane that reflects heat and welds at seams, while EPDM is a black rubber membrane that’s glued or taped. TPO works better in hot climates, EPDM excels in cold regions.

Can single-ply roofing handle extreme weather?

Yes, single-ply membranes are designed to withstand hail, high winds, and temperature extremes. Proper installation and regular maintenance ensure optimal performance in harsh conditions.

How much does single-ply roofing cost?

Single-ply roofing typically costs $3-8 per square foot installed, depending on membrane type and building complexity. The larger your roof, the lower the per-square-foot cost becomes.