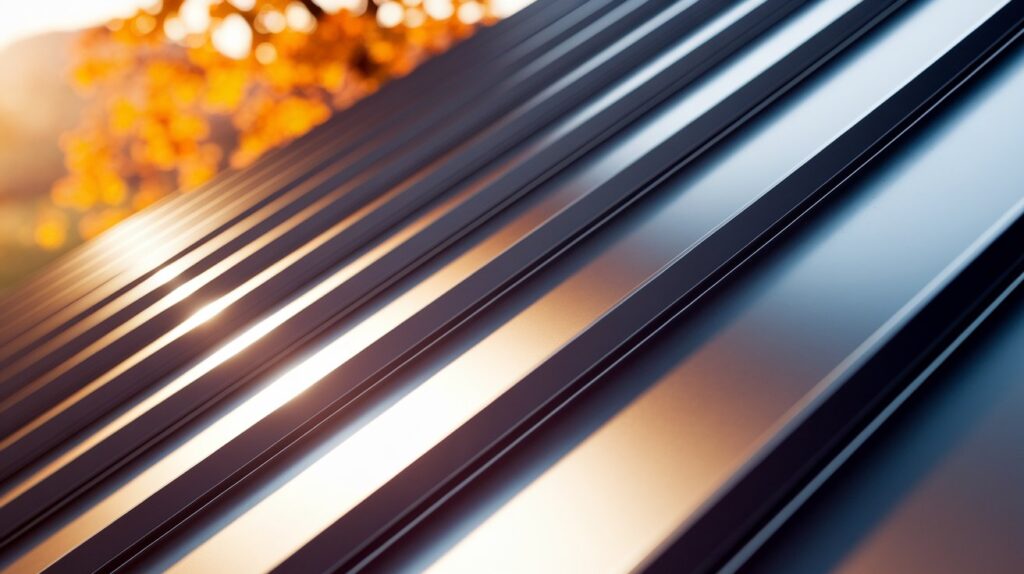

Metal roofing offers exceptional durability and long-term performance, enhancing the appearance of any home. Its ability to withstand decades of harsh weather, along with its clean appearance, makes it all the more desirable. However, not all metal roofs are created equal. The key to unlocking its full potential lies in identifying three important technical specifics: panel profiles, fastener systems, and the thermal movement. Making informed choices on these elements ensures your roof functions well and looks beautiful for generations. Here are five essential points to guide your selection.

Why Panel Profile Determines Performance and Aesthetics

The shape and configuration of the metal panels, the profile, is something more than a stylistic option; they decide, in effect, the weather performance, structural integrity, and installation difficulty of the roof. Standard profiles vary from the classic vertical ribs of corrugated panels to the robust, trapezoidal shapes of the 5-V Crimp or 7.2 panel to the sophisticated, smooth profiles of standing seam systems.

Trapezoidal and corrugated panels are a good value and an affordable choice for agricultural or functional construction, but their exposed fasteners do constitute a vulnerability. Standing seam panels, whose raised seams vertically overlap and cover the fasteners underneath, deliver enhanced weathertightness. It also offers a modern appearance and superior wind uplift resistance.

The vertical and horizontal span of the seams also affects the visual scale of the roof and its water- and snow-shedding capabilities. Choosing the right profile means balancing your budget and design goals. It also involves considering the local climate conditions to ensure long-term performance and curb appeal

Hidden vs. Exposed: The Critical Role of Fastener Systems

How the metal panels are fastened onto the roof deck is paramount to longevity and leak-free condition, and it is where fastener systems truly differ. Exposed fastener Systems, typical of corrugated and the majority of trapezoidal profiles, drive screws directly through the front of the panel into the roof deck or purlins.

While cheap and relatively simple to install, the exposed screws are areas of potential long-term leaks, and the rubber washers beneath them will inevitably deteriorate over time due to the effects of UV light and temperature cycling. They also provide a less aerodynamic appearance. Concealed Fastener Systems, used primarily with Standing Seam profiles, have clips held in place to the roof deck. The panel snaps or locks into place, completely hiding the fasteners from view.

This prevents direct penetration through the panel field, greatly enhancing weather resistance and providing a smooth, uninterrupted surface. Although typically requiring a higher front-end cost and more sophisticated installation expertise, concealed systems offer much superior long-term performance and an upscale look. The choice will rely on balancing front-end cost against long-term value and security.

Engineering for Thermal Movement

Metal shifts in size and shape significantly with temperature fluctuations, something that cannot be prevented. Failing to properly accommodate this thermal movement is a primary cause of premature roof failure. This includes oil-canning (visible waviness), fastener back-out, seam splitting, and structural stress.

Proper engineering involves several key strategies. Clip-based concealed fastener systems are inherently designed to allow panels to “float” and slide slightly as they expand and contract. The type and placement of these clips are crucial. For all systems, fasteners should never be driven too tightly; they need to allow for slight panel movement without binding. Strategic placement of expansion joints or slip splices in longer roof runs is essential to absorb significant movement.

Panel laps must also be designed and installed with movement in mind. The specific coefficient of expansion for the chosen metal (steel, aluminum, copper) and the expected temperature range extremes in the installation location directly influence these design calculations. A roof designed without meticulous attention to thermal movement is one that is destined for problems.

How Steel, Aluminum and Copper Influence the Choices

The base metal used for your panels isn’t about color; it interacts directly with profile, fastener, and thermal considerations. Galvanized or Galvalume Steel is the most common and cost-effective choice. It offers excellent strength. However, it requires robust paint systems or coatings for corrosion resistance and is heavier than aluminum. Its thermal expansion rate is moderate.

Aluminum is naturally corrosion-resistant, especially in coastal or industrial areas. It is also significantly lighter than steel. It expands and contracts nearly twice as much as steel for the same temperature change. This demands even more precise attention to clip design, fastener placement, and expansion joint spacing within the system.

Copper and zinc offer unparalleled longevity and develop a beautiful patina, but come at a premium cost and have their own unique expansion characteristics and installation nuances. The choice of metal affects the weight load on the structure and the overall system’s longevity. It also affects compatibility with fasteners (avoiding galvanic corrosion) and the necessary details for thermal movement. Selecting the profile and fastener system must be done in conjunction with choosing the base metal.

Integration and Installation: The Make or Break Factor

Even the best-engineered metal roofing system will underperform or fail if not installed correctly. This is where the intricate interplay of profile, fastener system, and thermal movement detailing comes together under the skill of the installer. Deck preparation must be flawless, flat, solid, and properly ventilated.

Starter strips, underlayment selection (synthetic is often preferred for its slip sheet properties), and edge metal details must be meticulously executed. For concealed fastener systems, clip placement must follow engineering specifications exactly to allow for the designed movement.

Fastener type (compatible with metal to prevent corrosion), torque, and placement are critical. This is especially in exposed systems where over-driving or under-driving can cause leaks or panel damage. Seams must be locked perfectly according to the manufacturer’s instructions. Complex roof features, such as valleys, dormers, and penetrations, require expert flashing integration. It should allow both water flow and thermal movement.

This level of precision underscores the importance of choosing experienced local professionals. For example, if you’re looking for roof installation in Albuquerque, working with experts who understand New Mexico’s extreme temperatures, shifts, and intense sun ensures your metal roof stands up to the elements for years to come.

Endnote

Choosing the best metal roof is a significant investment in your home’s future. By moving beyond aesthetics, you gain a deep understanding of panel profiles and the important differences between fastener systems. You also understand the non-negotiable need to accommodate thermal expansion and contraction. With this knowledge, you empower yourself to select a system that is engineered for decades of reliable and beautiful performance. Consulting professionals translate these technical choices into a roof that truly stands the test of time and weather.