After two decades working with concrete structures, I’ve seen countless property owners puzzled by the same question: “Why did my concrete crack when it’s supposed to last forever?”

While concrete stands as one of our most reliable building materials, cracking remains an inevitable reality that every contractor and homeowner faces.

Through years of field experience, I’ve learned that understanding why concrete fails isn’t just academic curiosity, it’s important knowledge that saves money and prevents headaches.

When you understand the root causes behind those frustrating fissures, you can make informed decisions about repairs, choose more effective prevention strategies, and set realistic expectations for your concrete investments.

Let’s examine what happens beneath the surface.

How Concrete Works and Why It Cracks

Having mixed thousands of batches over my career, I can tell you that concrete’s relationship with cracking starts the moment we pour it.

This remarkable material excels at handling compression: imagine trying to crush a concrete block with your hands. Yet when forces pull or bend it, concrete becomes surprisingly vulnerable.

Concrete’s Strength vs. Flexibility

Think of concrete like a strong but brittle cookie. It can support tremendous weight from above, but ask it to bend or stretch, and it snaps.

This fundamental limitation explains why we add steel reinforcement to concrete structures.

The steel handles tension while concrete manages compression, creating a partnership that works beautifully: until external forces exceed their combined capacity.

The Role of Temperature, Moisture, and Load

Temperature changes make concrete expand and contract like a giant breathing organism.

During hot summer days, slabs grow larger cold nights shrink them back. Meanwhile, moisture acts as both friend and enemy, essential during curing but destructive when it freezes inside the concrete matrix.

Load factors complete this trinity of stress. Every footstep, vehicle, or structural weight creates internal forces that gradually weaken the material’s integrity over time.

Common Causes of Concrete Cracks

From my years troubleshooting failed concrete, I’ve identified six primary culprits that cause most cracking problems.

1. Shrinkage Cracks

Concrete naturally shrinks as water evaporates during curing, creating internal tensions that pull the material apart.

This moisture loss happens unevenly, with surface areas drying faster than the interior, forming characteristic hairline cracks within days.

Prevention: Use lower water-cement ratios while maintaining workability. Install control joints every 8:10 feet to provide predetermined weak points where concrete can crack safely. Cover fresh pours to slow moisture evaporation.

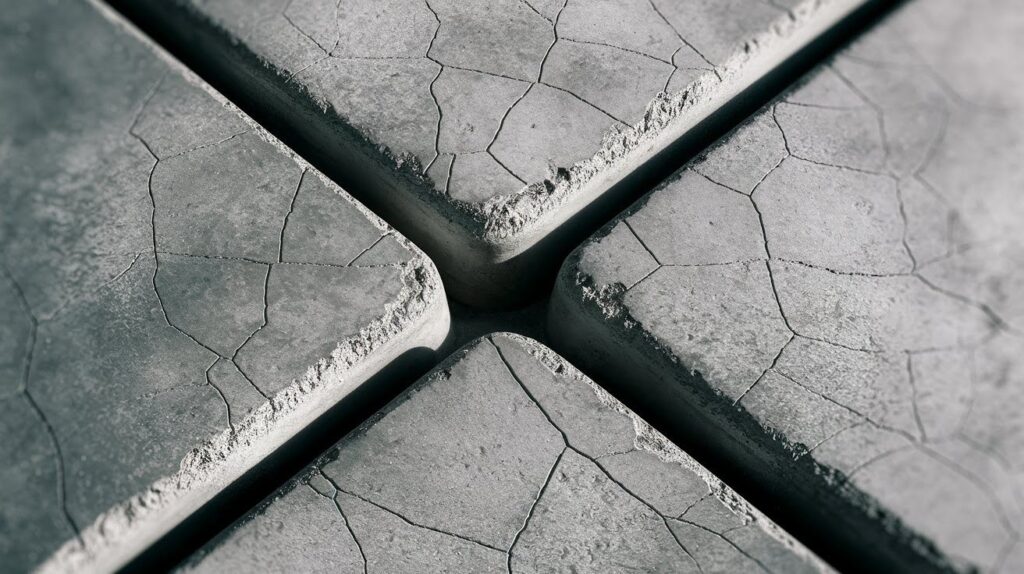

2. Re: Entrant Corner Cracks

Inward corners around manholes, columns, or decorative features create stress concentration points. These geometric changes disrupt normal force flow, causing cracks to radiate outward.

The concrete tries to shrink uniformly, but corners resist movement, creating predictable fracture points.

Prevention: Plan control joints to intersect vulnerable areas. Use diamond-blade saws to create clean joints that guide cracks along intended lines rather than random patterns.

3. Expansion Cracks

Summer heat makes concrete grow, and when expansion meets immovable objects, internal compression can exceed capacity.

Without proper relief mechanisms, the concrete develops stress that leads to cracking and structural failure.

Prevention: Install expansion joints between concrete sections. Fill gaps with compressible materials like closed-cell foam for standard applications or rubber strips for heavy traffic areas.

4. Heaving Cracks

Freeze-thaw cycles create concrete’s greatest challenge. Water trapped within expands 9% when frozen, creating internal pressures that can destroy the material.

Expansive clay soils compound this by swelling when wet, pushing slabs upward unevenly.

Prevention: Maintain proper drainage around structures. Avoid planting large trees within 20 feet of slabs, as their roots create soil instability and water demand issues.

5. Settlement Cracks

Poor soil preparation causes more failures than any other factor. When underlying soil shifts or compresses, concrete follows suit, creating stepped cracks and uneven surfaces.

Common causes include decomposing roots, improperly backfilled trenches, and insufficient compaction.

Prevention: Compact soil in 6-inch lifts using appropriate equipment. Remove all organic material and allow adequate settling time before pouring concrete over fill areas.

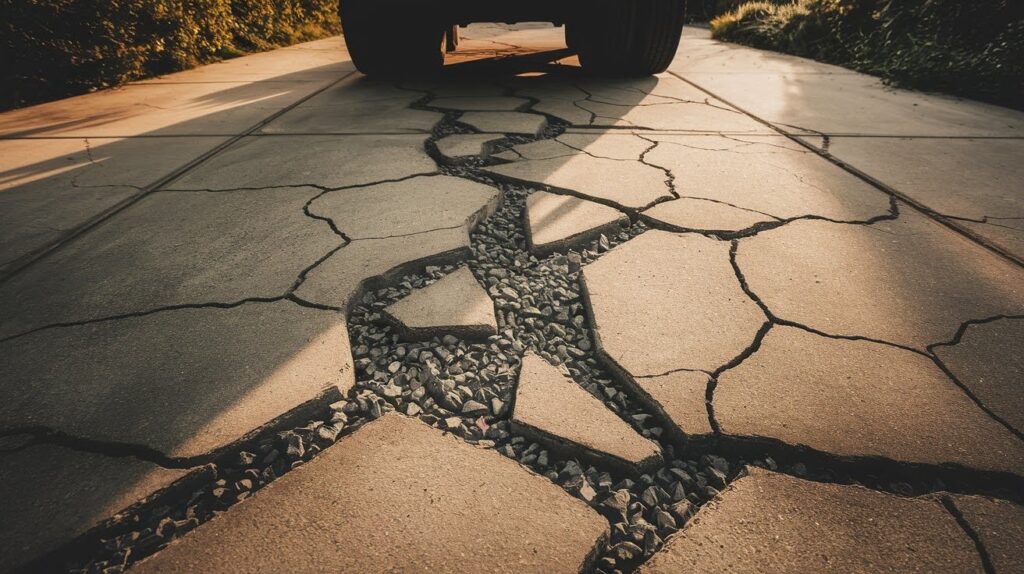

6. Excessive Weight Cracks

Every slab has load limits, yet these boundaries often get ignored.

Parking loaded trucks on thin residential driveways or placing heavy machinery creates point loads exceeding design specifications, causing sudden failures.

Prevention: Test existing concrete thickness before placing heavy equipment. Consult engineers for unusual loads and use temporary distribution methods like plywood or steel plates.

Environmental Factors Contributing to Cracks

Environmental conditions constantly attack concrete structures, creating stress that leads to cracking.

Freeze-thaw cycles pose the greatest threat as trapped moisture expands 9% when frozen, creating internal pressures that exceed concrete’s tensile strength. Each temperature fluctuation grows existing microcracks larger.

Chemical exposure from de: deicing salts, industrial chemicals, and acidic soils attacks concrete’s alkaline nature, dissolving the cement paste that binds aggregate particles.

Road salt proves particularly destructive by chemically weakening concrete while extending freeze-thaw seasons.

Fluctuating moisture levels create cyclical stress as groundwater rises and falls seasonally.

Foundations experience alternating wet:dry conditions, causing differential expansion and contraction.

This constant movement creates fatigue stress that gradually weakens the material, with structures near water sources showing horizontal crack patterns matching historical water level changes.

How to Minimize the Risk of Concrete Cracks

Preventing concrete cracks requires proactive planning and proper execution from design through construction. Success depends on addressing potential failure points before they become problems.

- Use Proper Mix Design: Lower water, cement ratios and add fiber reinforcement to reduce shrinkage and control micro-cracking during curing.

- Install Control and Expansion Joints: Place control joints every 8:10 feet and expansion joints between pours to manage thermal movement safely.

- Ensure Proper Subgrade Preparation: Remove organic material, compact soil in layers, and provide adequate drainage for stable foundation support.

- Follow Correct Curing Practices: Keep surfaces moist for seven days using wet coverings or curing compounds to prevent rapid moisture loss.

- Limit Overloading: Understand load limits and use distribution methods like plywood when heavy equipment crosses concrete surfaces.

- Maintain Proper Drainage: Grade away from foundations and install drainage systems to prevent water accumulation and freeze-thaw damage.

Conclusion

After decades in the concrete industry, I’ve learned that cracks aren’t random occurrences-they’re predictable results of specific causes.

Shrinkage, thermal expansion, poor soil preparation, environmental exposure, and overloading account for nearly every crack I’ve diagnosed. Understanding these root causes transforms you from a reactive property owner into a proactive one.

Here’s the most valuable lesson from my career: small cracks today become expensive problems tomorrow.

That hairline fracture you’re ignoring will grow with every freeze-thaw cycle, every heavy rain, and every temperature swing.

I’ve seen homeowners spend thousands on major repairs because they postponed addressing minor issues that could have been fixed for under a hundred dollars.

Don’t wait. Inspect your concrete regularly, seal small cracks promptly, and address drainage problems immediately. Your future self will thank you for the money saved and headaches avoided.

Frequently Asked Questions

What causes most concrete cracks in residential driveways?

Shrinkage during curing and poor soil preparation cause most residential concrete cracks. Temperature changes and inadequate control joints also contribute to common driveway failures.

Can small cracks in concrete become bigger problems?

Yes, small cracks allow water penetration that leads to freeze-thaw damage and structural deterioration. Addressing minor cracks early prevents costly major repairs later.

How long should I wait before walking on new concrete?

Wait 24-48 hours before light foot traffic and 7 days before vehicle traffic. Full-strength development takes 28 days, so avoid heavy loads during this period.

Do I need expansion joints in my concrete patio?

Expansion joints are essential for patios larger than 10×10 feet or when connecting to existing structures. They prevent cracking by allowing thermal movement between concrete sections.

Why does my concrete crack even in mild weather?

Internal shrinkage occurs regardless of weather as water evaporates during curing. Chemical reactions within concrete create stress that can cause cracking even without external temperature extremes.