Shipping has become a daily reality for many businesses, not just large warehouses and global retailers. Small online sellers, local manufacturers, subscription services, and even offices that send regular parcels all depend on smooth shipping workflows. In this environment, a shipping label printer plays a quiet but essential role. It is one of those tools that rarely gets attention until it is missing or causes delays.

At its core, a shipping label printer is designed to produce clear, scannable labels that include addresses, barcodes, tracking numbers, and handling information. These labels are not decorative. They are functional documents that connect a package to logistics systems, delivery routes, and customer expectations. When labels fail, shipments slow down or disappear entirely.

The Role of Shipping Labels in Daily Operations

Every shipped package relies on a label to move through sorting centers, vehicles, and delivery hubs. A readable label ensures that scanners can process parcels quickly and accurately. This matters because most shipping systems today are automated. Machines read barcodes, sort packages, and route them without human interpretation.

A shipping label printer helps businesses maintain consistency in this process. Labels printed at home or in the office are standardized, smudge-free, and properly sized. This reduces the chance of rejected shipments or manual corrections at drop-off points. Over time, that consistency saves effort and prevents repeated small errors that add up.

Why Thermal Printing Has Become the Preferred Method

Most modern shipping operations rely on a thermal label printer rather than traditional ink-based printing. Thermal printing works by applying heat to special label material, creating text and images without ink or toner. This method offers practical advantages that matter in real work settings.

First, thermal labels are more resistant to smudging. Ink can smear when exposed to moisture or friction, which is common during shipping. Thermal labels remain readable even after handling. Second, thermal printers require fewer consumables. Without ink cartridges, businesses spend less time replacing supplies and dealing with interruptions.

Another reason thermal printing matters is speed. A thermal label printer can produce labels quickly, which helps during peak shipping periods. Whether a business ships five packages a day or five hundred, speed affects productivity and stress levels.

Efficiency Beyond the Shipping Desk

A shipping label printer does more than create labels. It supports workflow efficiency across departments. When labels print the first time, packing stations move faster. Employees do not need to reprint labels or manually rewrite addresses. This reduces fatigue and errors, especially during busy seasons.

Accurate labels also improve communication with customers. Tracking numbers generated during label printing can be shared immediately. Customers receive updates sooner and can follow their shipments with confidence. This transparency builds trust, even though it happens quietly in the background.

Businesses that scale over time often notice that shipping problems grow faster than other issues. What worked for ten orders a week may fail at one hundred. Having a reliable shipping label printer in place early helps avoid that growing pain.

Supporting Different Business Sizes and Models

Shipping label printers are not limited to e-commerce warehouses. They are used in offices that send documents, repair centers returning equipment, healthcare facilities shipping supplies, and nonprofits mailing donations. Each setting has different volumes and requirements, but the need for accurate labeling is the same.

A thermal label printer adapts well to these environments because it is compact and relatively low-maintenance. It fits into tight workspaces and does not require frequent adjustments. This makes it suitable for shared offices or small packing areas where simplicity matters.

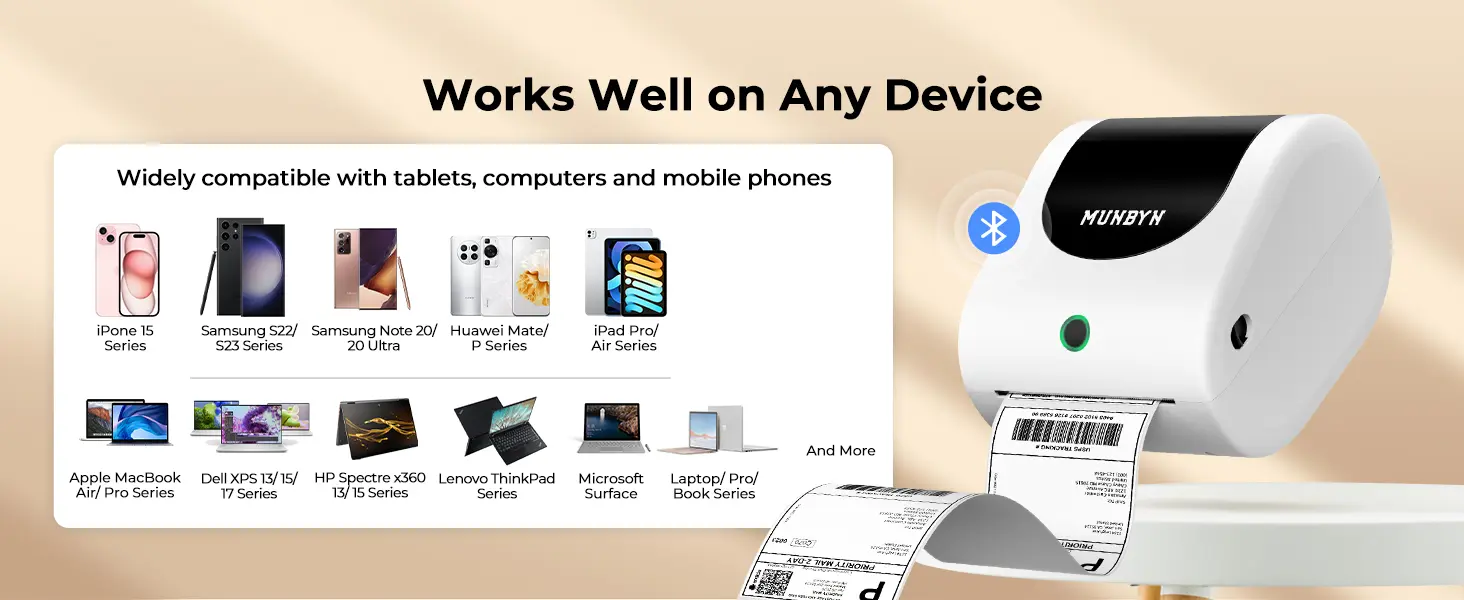

Some businesses choose tools from companies like Munbyn as part of their shipping setup. In these cases, the printer becomes a background utility. It is not the focus of daily work, but when it functions well, everything else moves more smoothly. Over time, Munbyn printers often become part of routine operations without drawing attention to themselves.

Cost Control and Long-Term Practicality

From a financial perspective, a shipping label printer can reduce long-term costs. Outsourcing label printing or using standard office printers leads to recurring expenses in ink, paper, and maintenance. Thermal printing minimizes these ongoing costs and simplifies inventory management.

There is also a hidden cost in time. Manually preparing labels or fixing printing mistakes pulls staff away from other tasks. A dependable thermal label printer reduces those interruptions. Over months and years, that saved time becomes meaningful.

Businesses using Munbyn solutions often mention reliability as a reason for sticking with thermal printing setups. While the brand itself is not the core issue, the idea of dependable printing highlights why this type of equipment matters in daily operations.

Reliability in High-Pressure Moments

Shipping deadlines are unforgiving. Missed pickup times or unreadable labels can delay deliveries by days. A shipping label printer provides control at a critical point in the shipping process. Instead of relying on external printing or handwritten labels, businesses manage this step internally.

During busy seasons, such as holidays or promotional periods, the pressure increases. A thermal label printer that performs consistently helps maintain order when volume spikes. Even when staff changes or temporary workers are involved, standardized printing reduces training time and confusion.

In many operations, Munbyn printers are used precisely because they simplify this high-pressure environment. The fewer variables involved in printing, the easier it is to keep shipments moving.

A Small Tool With a Broad Impact

It is easy to overlook the importance of a shipping label printer because it handles a single task. Yet that task connects directly to logistics, customer satisfaction, and operational efficiency. A label is the physical link between a business and the delivery network that serves it.

As shipping continues to be a core part of modern commerce, tools like the thermal label printer will remain essential. They support accuracy, speed, and reliability without demanding constant attention. For many businesses, that quiet dependability is exactly what makes them valuable.

Whether a company ships occasionally or operates at scale, the impact of choosing the right shipping label printer is felt every day. And as more operations look for simple, durable solutions, names like Munbyn continue to appear in conversations about dependable shipping workflows, from the first package of the day to the last.