What are the causes of white spots on plastic products and how do plastic manufacturers eliminate them?

In the production and application of plastic products, the appearance of white spots on the surface (commonly called “whitening” or “fogging”) is a frequent and troublesome problem. White spots not only affect the product’s appearance quality, but may also indicate defects in material properties or processing parameters. From a technical perspective, this article analyzes the main causes of white spot formation and outlines the prevention and elimination measures typically used by plastic manufacturers.

A. The main causes for the formation of white spots during the plastic manufacturing process

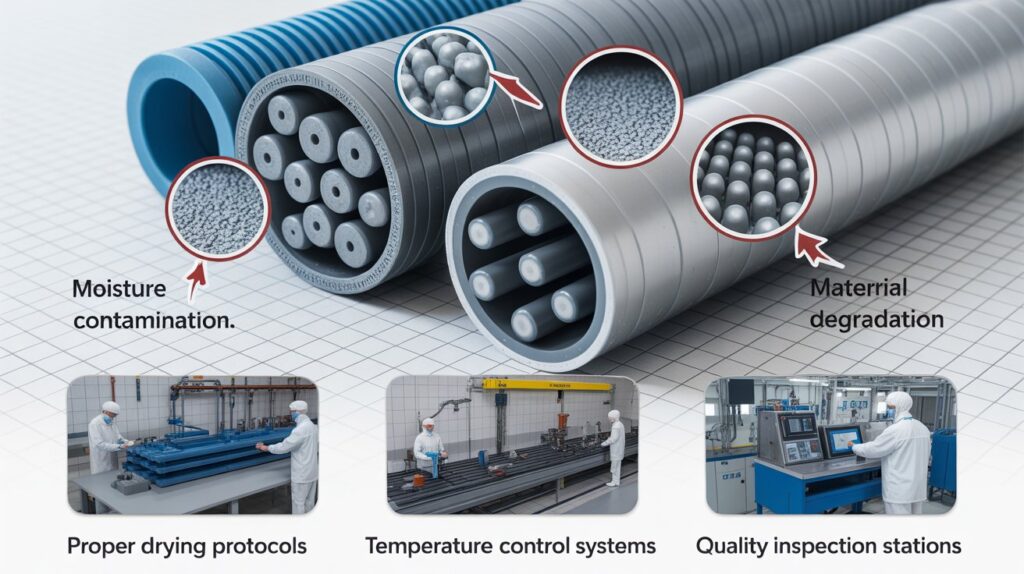

- Moisture and volatile components Many plastic raw materials (especially engineering plastics and thermoplastic resins) and additives such as fillers and auxiliaries contain certain amounts of moisture or low-boiling volatile substances. During high-temperature processing (injection molding, extrusion, blow molding), these moisture and volatiles evaporate and form tiny bubbles. When trapped near or at the surface during cooling and solidification, these bubbles create refractive index nonuniformities, which manifest on the surface as white spots or fogging.

- Low-surface-energy contaminants or lubricant residues Release agents, processing aids, or surface lubricants used during production that remain on the product surface or are incompatible with the matrix can form small phase-separated regions. These regions have different refractive indices from the matrix, causing light scattering and resulting in white spots. This is particularly likely in multilayer coatings or coextruded products, where poor interfacial adhesion more readily appears as white spots.

- Poor dispersion of fillers and reinforcement phases Inorganic fillers such as talc, calcium carbonate, and glass fiber are often added to plastics to improve properties or reduce cost. If these fillers are not well dispersed during processing or form micro-agglomerates, the local refractive index differences and changes in surface roughness will cause light scattering and produce white spots. Insufficient surface treatment of fillers can also create microvoids at the filler-matrix interface.

- Uneven mold cooling and sink marks/stress concentration In injection or blow molding, uneven mold temperature distribution or inconsistent cooling rates can cause local stress concentrations or nonuniform shrinkage. Stressed areas may develop microcracks or refractive index variations that scatter light, appearing as white spots or linear white marks.

- Entrapped gases and shear-degradation products High-shear processing or improper feeding can mechanically entrain air or gases into the melt likewise, excessively high processing temperatures or prolonged residence time can thermally degrade the resin, producing volatile low-molecular-weight species. These gases form small bubbles or microvoids during molding, which become visible as white spots after cooling.

- Optical anisotropy caused by surface stress Some semicrystalline or anisotropic resins can develop optical anisotropy (birefringence) or microstructural orientation differences under rapid cooling or high stress, causing local optical behavior that differs from the surroundings and becomes visible as white spots.

B. Technical measures manufacturers use to eliminate white spots

Raw material and formulation management

- Drying and moisture control: Strictly dry hygroscopic materials (such as PA, PBT, PC, etc.) before processing, use dehumidifying dryers, and monitor dew point/moisture content to ensure feedstock moisture is reduced below process requirements.

- Select low-volatility additives: Prefer processing aids and release agents with low volatility or high thermal stability to reduce volatiles that cause bubbles during processing.

- Surface treatment and compatibility improvement: Treat fillers with coupling agents or surface coatings to improve their wetting and dispersion in the matrix use compatibilizers to enhance interfacial bonding between different phases.

Process parameter optimization

- Temperature and shear control: Set barrel temperatures, screw speeds, and injection velocities appropriately to avoid excessive temperatures and shear that cause resin thermal degradation and gas generation.

- Holding pressure and cooling management: Optimize injection hold pressure, hold time, and mold cooling systems to reduce sink marks and internal stress, and to allow sufficient time for bubbles to escape or be suppressed.

- Venting and gate design: Improve cavity venting groove design and set gate location and size reasonably so processing gases can be discharged smoothly, reducing white spots caused by entrapped gases.

Equipment and mold improvements

- Efficient degassing and drying systems: Use melt degassing devices or vacuum drying systems to pre-degas extrudate or injection melt, lowering dissolved gas content.

- Optimize mold temperature control: Install more uniform or zoned controllable cooling circuits within molds, and use high-thermal-conductivity materials or heaters to prevent local temperature differentials that cause stress and white spots.

- Surface polishing and coatings: Mirror-polish mold cavities or apply wear-resistant coatings to reduce microscopic surface irregularities that lead to optical scattering.

Post-processing and surface treatment techniques

- Heat treatment to relieve stress: Anneal or heat-treat finished parts to release internal stresses and balance molecular orientation, thereby reducing stress-induced optical differences.

- Surface coatings and fill treatments: For finished parts with obvious surface white spots, apply thin-film coatings, spraying, or hot-air smoothing to modify the surface and cover or fill microvoids.

- Plasma or chemical cleaning: Remove residual release agents or contaminants on the surface to improve coating-substrate affinity and avoid secondary white spot formation.

Quality control and inspection

- Online and offline detection: Use online vision inspection systems or spectrophotometers to detect white spots, gloss, and haze establish traceable quality records and enable automatic removal of nonconforming parts.

- Failure analysis and feedback: Perform fracture-surface analysis, scanning electron microscopy (SEM), or Fourier-transform infrared spectroscopy (FTIR) on samples with severe white spots to identify causes and feed results back into formulation or process adjustments.

C. Conclusion

White spots are a composite expression of optical and surface-quality problems in plastic products, with causes involving raw material moisture, volatiles, filler dispersion, interfacial compatibility, mold cooling, and processing parameters. Plastic manufacturers can effectively prevent and eliminate white spots through strict raw material management (drying and surface treatment), optimized process parameters (temperature, hold pressure, venting), improved equipment and mold design (degassing, uniform temperature control), appropriate post-processing and surface modification methods, and the establishment of comprehensive quality inspection and feedback mechanisms. Ultimately, only through coordinated optimization of formulation, equipment, and process can manufacturers fundamentally improve product appearance uniformity and reliability to meet the market’s demand for high-quality plastic products.