Planning a shed foundation? You’re in the right place.

I’ll show you exactly how to build a skid foundation that lasts. This guide covers everything: materials, costs, step-by-step instructions, and when skids work best.

I’ve built over 50 shed foundations. Most were skids. They’re simple, cheap, and work great for most projects.

You’ll learn the complete process today. Site prep, leveling tricks, proper spacing, and anchoring methods. No guesswork needed.

I’ll also share the mistakes that cost me time and money. So you can avoid them. Your shed deserves a solid foundation. Let’s build one together.

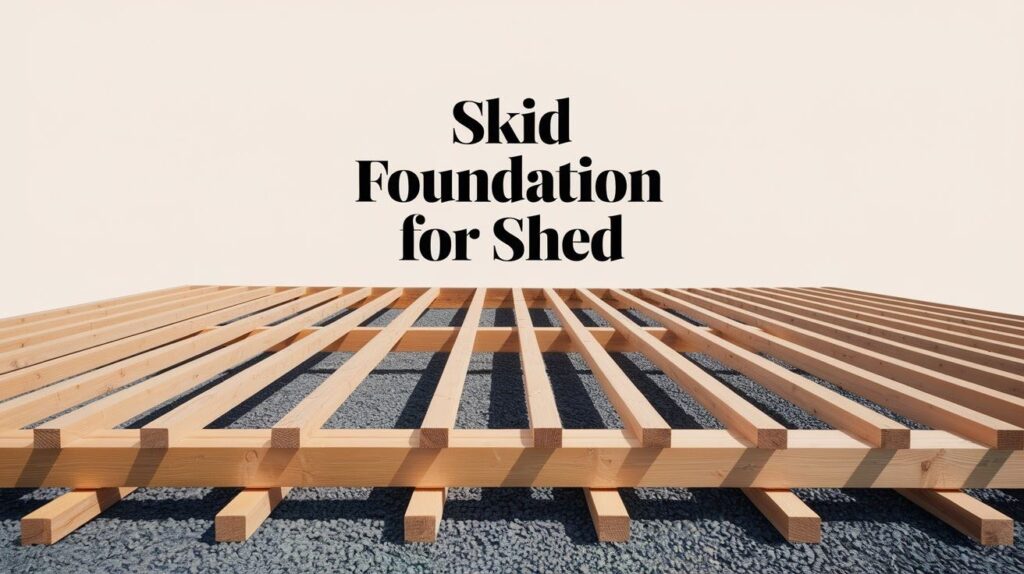

What is a Skid Foundation for a Shed?

A skid foundation is two or more long beams that sit directly on the ground. Your shed sits on top of these beams.

Think of it like putting your shed on skis. The skids spread the weight evenly across the ground. Most people use pressure-treated lumber for skids. Usually 4×6 or 6×6 beams work best.

The beauty? No concrete. No digging. No waiting for anything to cure. You can build your shed the same day you put down the skids.

Why Choose a Skid Foundation?

Let me share why I love skid foundations:

Cost-effective. You’ll spend maybe $50-150 on materials. Compare that to a concrete slab costing $500-2000.

Quick installation. I can set up skids in 2-3 hours. A concrete pad takes days. Portable. Need to move your shed later? Just lift it and relocate the skids.

Works on uneven ground. You can level skids much easier than pouring concrete on a slope. Great drainage. Water flows right under your shed. No pooling issues.

Building code friendly. Most areas don’t require permits for skid foundations.

I once had to move a client’s shed after a property line dispute. With skids, we relocated the entire 10×12 shed in one afternoon.

When NOT to Use a Skid Foundation

Skid foundations aren’t perfect for every situation.

Don’t use skids if your shed is larger than 12×16 feet. You live in an area with serious frost heave. Local codes require permanent foundations. You’re building on very soft or marshy ground.

Also skip skids for high-wind areas. Hurricane zones need anchored foundations.

I learned this during a storm in Florida. The shed stayed intact, but it moved three feet sideways!

Materials You’ll Need for a Skid Foundation

Here’s your shopping list:

For the skids:

- 2-3 pressure-treated 4×6 or 6×6 beams (length depends on shed size)

- Galvanized bolts or brackets for floor attachment

For the base:

- Landscape fabric

- 2-3 cubic yards of gravel

- Sand for leveling (1-2 bags usually enough)

Tools you’ll need:

- Level (4-foot minimum)

- Shovel

- Rake

- Measuring tape

- String line

- Stakes

Tip: Buy your lumber from a place that delivers. Those 6×6 beams get heavy fast.

Step-by-Step: How to Build a Skid Foundation for Your Shed

Ready to build? Let’s do this.

Step 1: Choose the Site & Clear the Area

First, pick your spot carefully.

Look for level ground. Good drainage. Easy access for materials. At least 3 feet clearance from property lines. Clear everything from the area. Grass, weeds, rocks, debris. Everything.

I like to mark the area with spray paint first. Makes the clearing process much faster.

Size tip: Make your cleared area 2 feet larger than your shed on all sides. You’ll need the extra room to work.

Step 2: Level the Ground and Add Gravel Base

This step makes or breaks your foundation. Scrape away 4-6 inches of topsoil. You want to get down to solid subsoil.

Here’s my leveling trick: Use a long 2×4 and a level. Drag it across the area to find high and low spots.

Add your gravel base. I prefer 3/4-inch crushed stone. Spread it 4 inches thick. Rake it smooth. Then compact it down. No compactor? Drive your car back and forth over it slowly. Works well for small areas.

Lay landscape fabric over the gravel. This prevents weeds from growing up through your foundation.

Step 3: Lay Out Skids (Spacing, Alignment & Squaring Tips)

Time for the fun part.

Standard spacing: Place skids 4-6 feet apart for most sheds. Smaller sheds can go 8 feet apart. Position your first skid along one edge of your cleared area.

Here’s how I ensure perfect alignment: Set up string lines parallel to your first skid. Use these as guides for the other skids.

Squaring method that never fails: Measure diagonals between skid ends. Adjust until both diagonals are exactly equal. Double-check with your measuring tape.

The skids should extend slightly beyond your shed footprint. About 6 inches on each end works well.

Step 4: Secure the Shed Floor Joists to Skids

Your floor joists need solid attachment to the skids. I use galvanized brackets. They’re stronger than just nailing through.

Space your joists 16 inches on center. This gives you a rock-solid floor.

Attachment options: Joist hangers (my favorite). Galvanized bolts through the skids. Heavy-duty construction screws.

Make sure each joist sits flush on top of the skids. No gaps, no wobbling.

Quality check: Walk on your floor frame. It should feel completely solid.

Step 5: Anchoring for Wind Resistance

Don’t skip this step. Even skid foundations need anchoring.

Simple anchoring methods: Ground anchors screwed into the earth. Concrete blocks placed against the skids. Metal straps connecting skids to buried deadmen.

I prefer ground anchors. They’re easy to install and very effective. How many anchors? Plan on 2-4 anchors for most sheds. More for larger buildings or windy areas.

Connect the anchors to your skids with galvanized cables or straps.

Skid Foundation Dimensions & Spacing Guidelines

Let me give you some proven measurements:

| Shed Size | Skid Size | Skid Length | Skid Spacing | Number of Skids |

| 8×10 | 4×6 | 10 feet | 6 feet apart | 2 |

| 10×12 | 4×6 or 6×6 | 12 feet | 8 feet apart | 2 |

| 12×16 | 6×6 | 16 feet | 6 feet apart | 3 |

General rule: Never space skids more than 8 feet apart. Your floor will sag.

Skid thickness matters too. 4×6 works for sheds up to 10×12. Go with 6×6 for anything larger.

Cost Breakdown: How Much Does a Skid Foundation Cost?

Let’s talk about money. Here’s what you can expect to spend:

Materials for typical 10×12 shed:

| Item | Cost Range |

| Pressure-treated 4×6 skids (2) | $60-80 |

| Gravel (2 yards) | $40-60 |

| Landscape fabric | $20-30 |

| Brackets and hardware | $30-50 |

| Sand | $15-25 |

| Total Materials | $165-245 |

Labor costs (if hiring someone):

| Service | Cost Range |

| Labor | $200-400 |

| Total Project Cost | $365-645 |

Compare to other foundation types:

| Foundation Type | Cost Range |

| Skid Foundation | $165-645 |

| Concrete Slab Foundation | $800-2000 |

| Block Foundation | $600-1500 |

You can save serious money with skids.

Money-saving tips: Buy lumber during off-season sales. Get gravel delivered in bulk. Borrow tools instead of buying.

When to spend more: Don’t cheap out on the pressure treatment. It’s your insurance against rot.

Conclusion

You now have everything you need to build a solid skid foundation. I’ve shared my 20 years of experience in this guide.

Start with proper site prep. Take your time leveling the ground. Don’t rush the gravel base. These steps matter most.

Remember to anchor your foundation properly. I’ve seen too many sheds move during storms. Learn from my mistakes.

Your skid foundation will last 15-20 years with minimal care. That’s great value for your money.

Ready to start building? Gather your materials this weekend. Your shed project is closer than you think.

Need help with your specific situation? The methods I’ve shown work for most projects. Adapt them to your needs.

Now go build something you’ll be satisfied with.

Frequently Asked Questions

How long do skid foundations last?

Most skid foundations last 15-20 years with basic maintenance. I’ve seen well-built ones go 25 years in good conditions.

Can I build a skid foundation on clay soil?

Clay soil works fine if you add proper drainage. Use extra gravel and make sure water can flow away from your foundation.

Do I need a building permit for a skid foundation?

Most areas don’t require permits for skid foundations since they’re not permanent. Always check with your local building department first.

What’s the maximum shed size for skid foundations?

I recommend staying under 12×16 feet for skid foundations. Larger sheds need more support than skids can provide safely.

Should I use treated or untreated lumber for skids?

Always use pressure-treated lumber for skids. The extra cost is worth it to prevent rot and extend your foundation’s life.