After installing over 200 garage floor coatings in my career, I’ve seen firsthand how the right choice can make or break a homeowner’s satisfaction.

Your garage floor endures constant abuse, hot tire marks, chemical spills, temperature fluctuations, and heavy equipment. The coating you select determines whether you’ll enjoy decades of durability or face costly repairs within years.

Two premium options dominate today’s market: Polyurea and Polyaspartic coatings. Polyurea offers rapid curing and exceptional flexibility, while Polyaspartic provides superior UV stability and extended working time. Both outperform traditional epoxy, but each has distinct advantages.

In this comprehensive comparison, I’ll break down performance characteristics, application requirements, costs, and real-world durability. By the end, you’ll confidently choose the coating that best matches your specific needs, budget, and expectations for your garage space.

Understanding the Basics

Essential knowledge about polyurea and polyaspartic coatings, including their chemical compositions, properties, and primary applications in flooring.

What is Polyurea?

Polyurea forms through the reaction of isocyanates with polyamines, creating an extremely durable, flexible membrane that bonds well to concrete.

This coating offers remarkable resistance to abrasion, chemicals, and temperature extremes while maintaining elasticity that prevents cracking.

In flooring applications, polyurea serves high-traffic commercial spaces, industrial facilities, and residential garages.

Its rapid cure time enables quick project completion, while the seamless finish provides easy maintenance. Beyond flooring, polyurea excels in waterproofing, truck bed liners, and protective coatings where durability matters most.

What is Polyaspartic?

Polyaspartic coating is a specialized subset of polyurea technology, using aliphatic polyisocyanates combined with polyaspartic ester. This formulation creates extended working time and enhanced UV stability compared to standard polyurea.

Polyaspartic stands out for its ability to cure at lower temperatures while offering superior color retention and gloss stability under sunlight exposure.

These characteristics make it valuable for decorative applications where appearance longevity matters. Additionally, it can be applied in thicker films without compromising performance, ideal for floors requiring both visual appeal and industrial-strength protection.

Side-by-Side Comparison

| Feature / Factor | Polyurea | Polyaspartic |

| Durability | Extremely durable, impact-resistant | High durability with excellent wear resistance |

| UV Stability | Moderate – may yellow over time | Excellent – superior UV resistance |

| Curing Time | Very fast (minutes) – can be challenging to work with | Moderate (hours) – more forgiving for application |

| Installation Difficulty | Requires skilled installers due to speed | Easier for pros, some DIY possibilities |

| Temperature Flexibility | Handles extreme temps well | Handles extreme temps equally well |

| Color & Gloss Retention | Good, but may fade outdoors | Excellent long-term gloss and color retention |

| Cost | Slightly lower material cost | Slightly higher due to advanced formulation |

| Best Use Case | Industrial floors, cold climates | Garage floors, outdoor areas with sun exposure |

Pros and Cons at a Glance

Quick comparison of key advantages and disadvantages for both coating types to simplify your selection process.

Polyurea Pros and Cons

Pros:

- Lightning-fast cure times enable same-day use

- Exceptional impact resistance and flexibility

- Excellent chemical resistance and stain protection

- Lower material costs • Performs well in extreme temperatures

Cons:

- Requires highly skilled installers due to rapid curing

- May yellow under UV exposure over time

- Limited working time makes corrections difficult

- Needs specialized spray equipment

Polyaspartic Pros and Cons

Pros:

- Extended working time for better application control

- Outstanding UV stability maintains color and gloss

- More forgiving for professional installers

- Excellent decorative potential with color options

- Superior long-term appearance retention

Cons:

- Higher material costs increase project investment

- Slower cure times extend completion schedules

- Still requires professional installation for best results

- Limited availability compared to standard options

The Best of Both Worlds: Hybrid Systems

Smart contractors combine both technologies to maximize performance benefits while minimizing individual coating limitations for superior results.

Why Some Contractors Use Both

Benefits of a Polyurea Basecoat + Polyaspartic Topcoat

The hybrid approach combines polyurea’s rapid strength development with polyaspartic’s superior surface properties.

The polyurea base provides exceptional concrete adhesion and quick moisture barrier formation, while the polyaspartic topcoat adds critical UV protection and color stability.

This combination delivers structural benefits with aesthetic longevity. The polyaspartic layer offers better chemical resistance to automotive fluids and easier maintenance than polyurea alone.

Real-World Performance

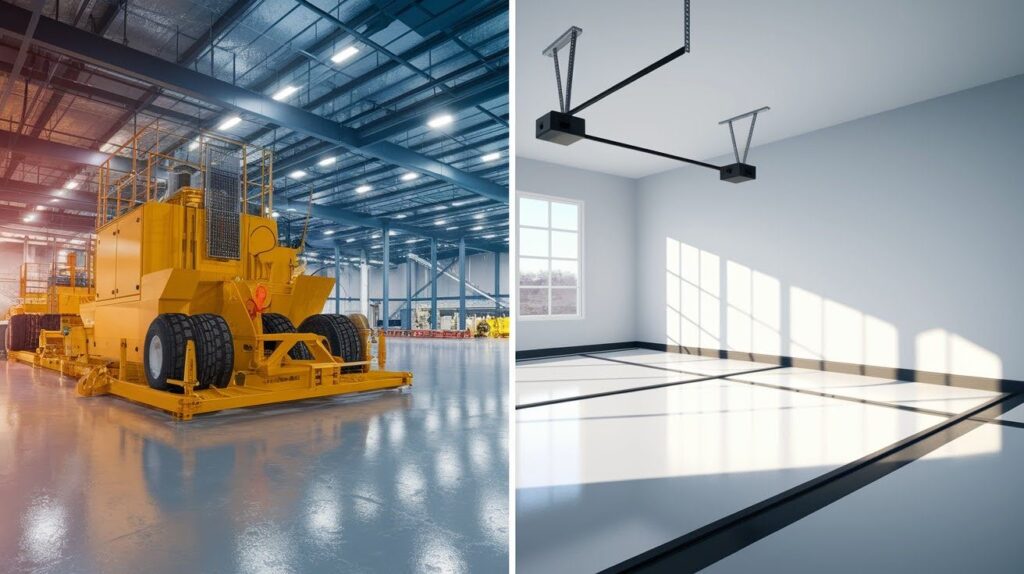

How Hybrid Systems Perform in Garages and Commercial Settings

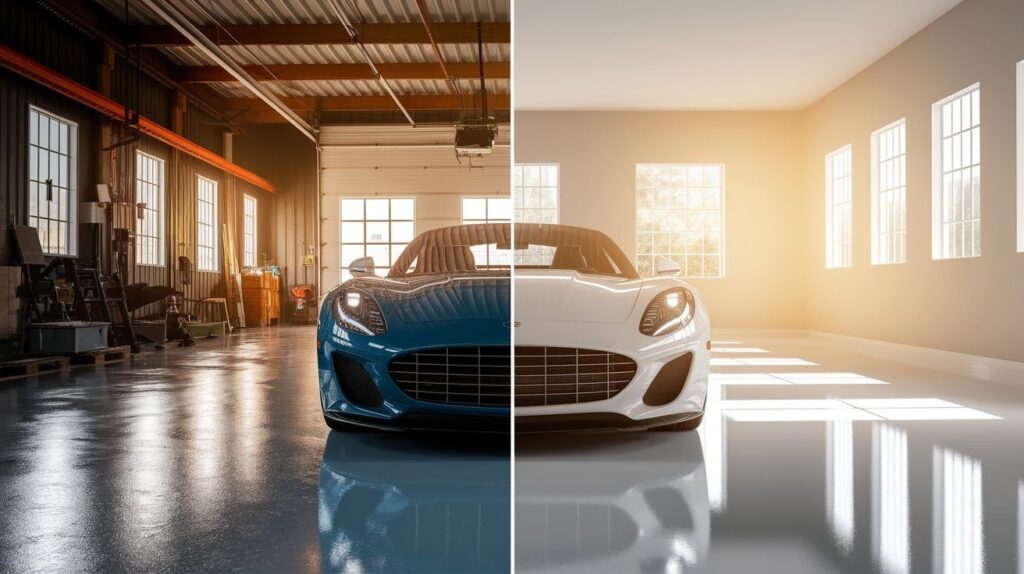

In residential garages, hybrid systems consistently outperform single-coating applications. The polyurea base handles thermal shock from hot tires, while the polyaspartic top layer maintains appearance despite UV exposure.

Commercial facilities benefit from handling heavy traffic loads while maintaining professional standards.

Manufacturing plants and automotive service centers report excellent long-term performance with minimal maintenance. The system cures quickly at the base level while providing extended working time for decorative topcoats.

Which One Should You Choose?

Selecting the right coating depends on your specific circumstances, performance expectations, and long-term goals for your flooring investment.

Key Factors to Consider:

- Climate Impact: Cold regions with freeze-thaw cycles benefit from polyurea’s superior flexibility, while areas with intense sunlight require polyaspartic’s UV resistance

- Sun Exposure: South-facing garage openings and high UV environments demand polyaspartic’s color stability and gloss retention

- Budget Analysis: While polyurea costs less upfront, potential recoating needs may increase long-term expenses compared to polyaspartic’s extended service life

- Project Type: Industrial applications prioritize durability over appearance (favoring polyurea), while residential garages benefit from polyaspartic’s aesthetic longevity

- Installation Skill Level: DIY enthusiasts should avoid polyurea due to application complexity polyaspartic offers more manageable installation windows

Our Recommendation:

- Residential Garages: Polyaspartic wins for most homeowners due to forgiving application, superior UV stability, and excellent long-term appearance

- Industrial Settings: Choose polyurea for cold climates, rapid return to service needs, and applications prioritizing impact resistance over aesthetics

- Premium Applications: Consider hybrid systems when budget allows, maximizing both performance and aesthetics through superior long-term results

Conclusion

After decades in the coating industry, I’ve learned that both polyurea and polyaspartic have their place in quality floor protection.

Polyurea excels in demanding industrial environments and cold climates where rapid curing and flexibility matter most.

Polyaspartic shines in residential garages and sun-exposed areas where long-term appearance and UV stability are priorities.

The key differences boil down to application complexity, cure times, UV resistance, and cost considerations.

While polyurea offers speed and durability, polyaspartic provides forgiveness and longevity. Hybrid systems combine the best of both worlds for premium applications.

My strongest advice? Consult with experienced professionals before making your final decision.

Every project has unique requirements, and a qualified contractor can assess your specific conditions, budget, and expectations to recommend the optimal solution for your space.

Frequently Asked Questions

Which coating cures faster – polyurea or polyaspartic?

Polyurea cures extremely rapidly, often within minutes, making it challenging for inexperienced installers to work with it effectively. Polyaspartic offers a more manageable cure time of several hours, providing better control during application while still achieving the same-day use.

Can I apply these coatings myself, or do I need a professional?

Polyurea requires professional installation due to its rapid cure time and need for specialized spray equipment. Polyaspartic is more DIY-friendly for experienced home improvers, though professional installation still ensures optimal results and warranty coverage.

Which coating handles UV exposure better?

Polyaspartic significantly outperforms polyurea in UV resistance, maintaining color and gloss even under direct sunlight exposure. Polyurea may yellow or fade over time when exposed to UV rays, making it less suitable for outdoor applications.

What’s the cost difference between these two coatings?

Polyurea typically costs less in material expenses but requires skilled professional installation, which can increase labor costs. Polyaspartic has higher material costs due to its advanced formulation but may offer better long-term value through reduced maintenance needs.

Which coating is better for cold-weather applications?

Both coatings handle temperature extremes well, but polyurea has a slight advantage in flexibility during freeze-thaw cycles. Polyaspartic performs equally well in cold conditions while offering superior application windows in varying weather conditions.