When selecting materials for construction, DIY projects, or furniture making, engineered wood panels offer versatile solutions that combine affordability with functionality.

Two of the most popular options are Oriented Strand Board (OSB) and plywood, each bringing distinct characteristics to your project needs.

Understanding the differences between these materials is essential for making informed decisions that impact both your budget and project outcomes.

Key factors like cost, structural strength, moisture resistance, and visual appearance play crucial roles in determining which option best suits your specific application.

Making the right choice between OSB and plywood can significantly affect your project’s durability, performance, and overall success.

This comparison will help you evaluate both materials based on their unique properties and practical applications.

What is OSB (Oriented Strand Board)?

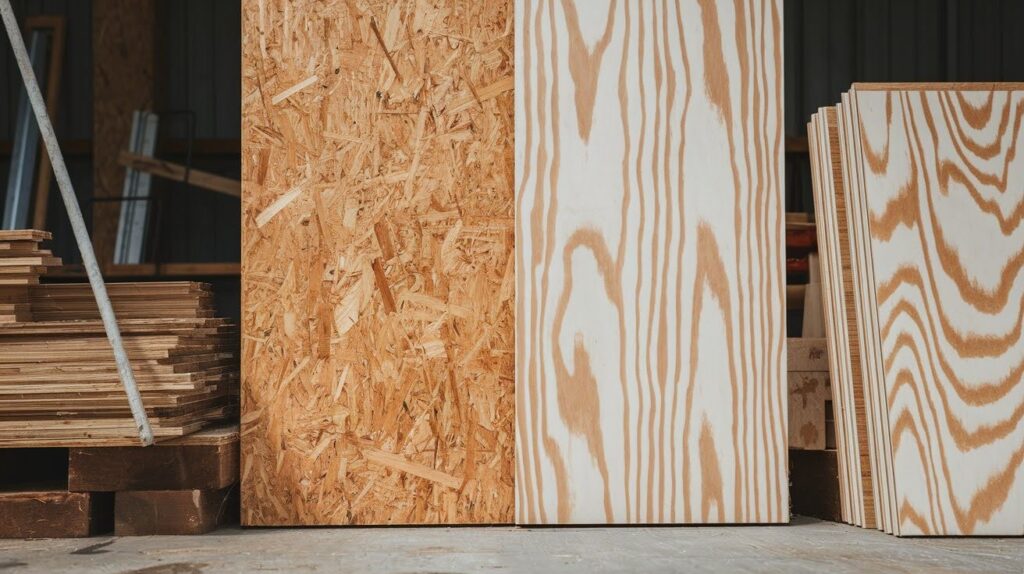

OSB is an engineered wood panel made from cross-layered wood strands bonded with resin and hot-pressed into strong, affordable sheets.

How OSB is Made

OSB is manufactured through a precise process that begins with wood strands arranged in cross-layered patterns.

These strands are coated with resin adhesives and then subjected to high heat and pressure during the hot-pressing stage.

This method creates panels with engineered strength properties that distribute load effectively across the board’s surface.

The manufacturing process ensures consistent density throughout each panel, making OSB a reliable choice for structural applications where uniformity matters.

Key Characteristics of OSB

- OSB features a distinctive industrial appearance with visible wood strands creating a textured surface pattern.

- This engineered material offers consistent density throughout each panel, providing predictable performance characteristics.

- One of OSB’s most appealing qualities is its affordability compared to other engineered wood products.

- Despite its lower cost, OSB maintains impressive structural strength, making it suitable for load-bearing applications in construction and building projects where budget considerations are important.

What is Plywood?

Plywood is an engineered wood panel made from thin veneers glued with alternating grain directions, offering smooth surfaces and excellent stability.

How Plywood is Made

Plywood is constructed by layering thin wood veneers with alternating grain directions, then bonding them together using strong adhesives.

This cross-grain construction creates exceptional stability and prevents warping or splitting along natural wood grain lines.

Manufacturing processes vary depending on the intended use, with plywood available in multiple grades ranging from construction-grade to furniture-quality finishes.

Different wood species can be used for face veneers, allowing for various aesthetic and performance options to match specific project requirements.

Key Characteristics of Plywood

- Plywood offers smooth, decorative surfaces that work well for visible applications where appearance matters.

- The face veneers can showcase natural wood grain patterns, making it suitable for furniture, cabinets, and interior finishing work.

- This engineered material provides excellent strength-to-weight ratios and dimensional stability.

- The alternating grain structure distributes stress evenly, reducing the likelihood of warping, cracking, or splitting that can occur with solid wood products, making plywood a dependable choice for both structural and aesthetic applications.

Comparison Table: OSB vs. Plywood

|

Feature |

OSB (Oriented Strand Board) |

Plywood |

|

Composition |

Strands of wood + resin |

Thin wood veneers glued in layers |

|

Surface Finish |

Rough and patchy |

Smooth, can be decorative |

|

Strength |

Strong but flexible across width |

Stiff and strong in both directions |

|

Moisture Resistance |

Resists water but swells when soaked |

Resists swelling; dries back better |

|

Weight |

Heavier |

Lighter |

|

Cost |

15–30% cheaper |

More expensive |

|

Workability |

Cuts easily but edges splinter |

Easy to cut, screw, and finish |

|

Aesthetics |

Not suitable for visible use |

Great for cabinetry, furniture, visible areas |

|

Eco-Friendliness |

Made from fast-growing softwoods |

Requires large-diameter, often slow-growing wood |

Pros and Cons of Each Material

OSB offers budget-friendly strength but poor moisture resistance, while plywood provides attractive finishes and durability at higher costs.

Pros of OSB

- Budget-friendly option that makes it accessible for large-scale construction projects and cost-conscious builders

- Uniform density throughout each panel ensures consistent performance characteristics across the entire board

- Strong structural properties with widespread availability at most lumber yards and home improvement stores

Cons of OSB

- Swells significantly when exposed to moisture and recovers slowly once dried, creating permanent dimensional changes

- Industrial appearance with visible wood strands makes it unsuitable for applications where aesthetics matter

- Tends to splinter when cut, requiring careful handling and potentially additional finishing work around exposed edges

Pros of Plywood

- Attractive finish that works well for visible applications, furniture making, and cabinet construction

- Layered construction provides exceptional stiffness and reliability for structural applications

- Demonstrates impressive longevity under stress conditions, maintaining structural integrity over extended periods

Cons of Plywood

- Higher cost with plywood typically commanding premium prices compared to other engineered wood options

- Quality issues can arise through delamination, where layers separate due to adhesive failure or moisture exposure

- Premium grades tend to be heavier than standard options, complicating handling and requiring additional structural support

Best Applications for OSB and Plywood

OSB works best for structural applications like subflooring and roofing, while plywood suits furniture, cabinetry, and moisture-prone areas.

When to Use OSB

OSB works exceptionally well for subflooring applications where structural performance matters more than appearance. The material’s consistent density and strength properties make it suitable for supporting floor loads while keeping project costs manageable.

Roofing applications benefit from OSB’s affordability and structural capabilities. When covered with proper roofing materials, OSB provides adequate protection and load distribution for residential and commercial buildings.

Budget-focused framing projects often rely on OSB for sheathing and structural components where visual appeal isn’t a concern. The material’s lower cost allows builders to allocate more budget to other project elements while maintaining structural requirements.

When to Use Plywood

Furniture making applications showcase plywood’s smooth surfaces and attractive grain patterns. The material’s dimensional stability prevents warping and splitting that could compromise furniture quality over time.

Cabinetry and shelving projects benefit from plywood’s clean appearance and ability to hold screws securely. The smooth surfaces accept stains, paints, and finishes well, creating professional-looking results.

Wet areas require marine or treated plywood varieties that resist moisture damage better than standard materials. Bathrooms, kitchens, and exterior applications often specify these specialized plywood types for long-term performance.

Conclusion

The choice between OSB and plywood depends on several critical factors that align with your specific project requirements.

OSB offers cost-effective solutions for structural applications like subflooring and roofing where appearance isn’t a priority, while plywood excels in furniture making, cabinetry, and visible installations requiring smooth finishes.

Consider your project type carefully – structural work often benefits from OSB’s affordability, whereas decorative applications call for plywood’s superior aesthetics.

Moisture exposure levels should guide material selection, with plywood generally performing better in wet conditions.

Budget constraints may favor OSB for large-scale projects, while finish quality requirements often justify plywood’s higher cost.

Evaluate these factors against your specific needs to make the most appropriate material choice for successful project outcomes.

Frequently Asked Questions

Is OSB stronger than plywood?

Both materials offer good strength, but they perform differently under various conditions. Plywood provides consistent strength in all directions due to its cross-grain construction, while OSB offers excellent load-bearing capacity but can be more flexible.

Which material costs less – OSB or plywood?

OSB typically costs 15-30% less than plywood, making it the more budget-friendly option. This cost difference makes OSB popular for large construction projects where appearance isn’t a primary concern.

Can OSB be used in wet areas?

OSB swells significantly when exposed to moisture and doesn’t recover well once dried. For wet areas like bathrooms or exterior applications, marine-grade or treated plywood is the better choice.

Which material looks better for furniture projects?

Plywood offers smooth, attractive surfaces that work well for visible applications like furniture and cabinetry. OSB has an industrial appearance with visible wood strands that isn’t suitable for decorative uses.

How do OSB and plywood compare for subflooring?

Both materials work for subflooring, but OSB is more commonly used due to its lower cost and adequate structural performance. Plywood may be preferred in moisture-prone areas or when a smoother surface is needed.